| Product Ranges | Plastic Springs, Stamping Punches, Stamping Dies Matrixes, Tungsten Carbide Parts, Guide Lifters, Guide Pins and Bushings, Special Tooling, Ejector Pins Sleeves, Guiding Elements, Injection Elements, Centering Elements, Date Stamp, Mold Base, Mold Springs, Bolts, Press Fittings, Guiding Components, CAM Components, Thick Turret Tooling, , Murata Wiedemann Tooling, Thin Turret Tooling, Salvagnini Tooling, High Performance Coating, Multi-Tools, Turning and Milled parts, CNC Milling Machining Parts, CNC machined parts. More products can be produced according to "MISUMI",, "DANLY", "DME", "HASCO", "TOHATSU", "FIBRO", "AGATHON", "STRACK", "PEDROTTI", "RAYMOND", "FUTABA","SANKYO", "PROGRESSIVE", "RABOURDIN", etc., or as customers' drawings. |

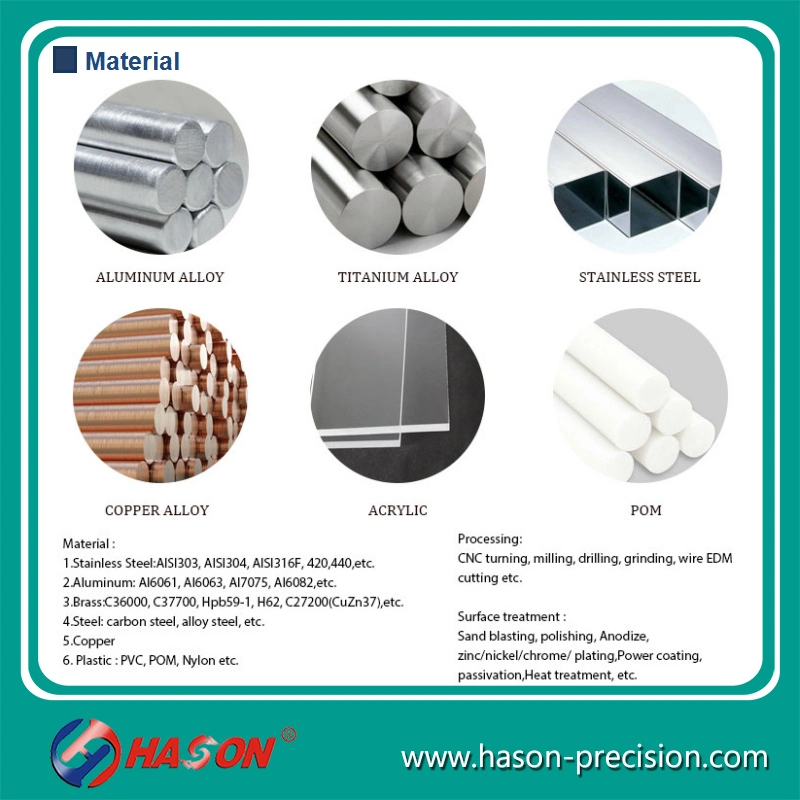

| Material | Steel, Brass, Copper, Stainless steel,Tool Steel, Free cutting steel, Carbon steel, Plastic, Aluminium, POM, Delrin,Titanium Alloy etc. |

| Hardness | Depend on Material |

| Coating | TiN / TiCN /AlTiN / TiAlN / AICrN / CrN / DLC / AlCrTlN / TiCrN / DUPLEX |

| Surface treatment | Nitriding/Blackening/Plating/Painting/Polishing/Brushing/Galvanize/Passivation/Shot-blast/Texture, or according to customer's requests. |

| Equipments | CNC machine, Automotic lathe machine, EDM machine, Stamping lathes,Wire-cutting machine, Milling/Grinding machine, Punching/Drilling machine, Ultrasonec cleaning machine, etc. |

| Service | OEM & ODM |

| Design | Standard/Customized |

| Tolerance | +/- 0.002mm |

| Roughness | Close to Ra0.02 |

| Standard | DAYTON,LANE,DIN,ISO,MISUMI,EDM,FIBRO,MOELLER,HASCO,ETC. |

| Certificate | ISO |

| Packing | Inner packing with recycle plastic box and anticorrosive oil, outer with sponge and PE bags, or as customer's requirements. |

| Payments | T/T, L/C, Paypal, Western Union |

Advantages:

1) The precision machined keyway can accommodate the heat-treated punches lacating key, without any jig, you can follow the position of the die to make precise positioning.

2) Precision grinding upper and lower surfaces can take the initiative connected with punches shoulder, which reduce punch body stress and extend tooling life.

3) Make rigid connection between the punch body locating key and adjustment ring keyway, eliminating the possibility of punch body relative displacements.

4) Using seismic tool steel to eliminate scratches and extend using life.

5) Is compatible with traditional Size 2 punch body.

6) Is interchangeable with QuickLock™ size1 and size2 punch body.

Applicable machine models: Various new and old model, Size I, Size II, 0-A, 0-B station, MT10, MT5 etc.

QC Facility&Process

These products are showed here only to present the capability of our business activities,

Our company specialized in manufacturing and designing of various non-standard precision parts, our service cover mechanical engineering, electronic engineering, semiconductor, tele-communication, medical equipment, automation equipments etc. We invested advanced manufacturing equipments(such as high-speed CNC Machining Center, Grinding machines, Milling machines, NC lathe, Stamping machine, Wire-Cutting machines)and quality testing machines(such as coordinate measurement machine, Micro-projector and Height Gauge etc. ) we can also provide one-stop shopping OEM.

All parts can be machined with tiny tolerance, precise dimensions and a smooth surface. Roughness typically considered to be the high frequency, short wavelength component of a measured surface.

Our Advantages:

1. Competitive price: based on reasonable calculation, our price is always competitive which can support customers at the first round of competition

2. Consistent quality control: parts are made by our experienced staffs that can control the parts to exact dimensions in the process of production. On the other hand, our experienced QCs inspect all the parts thoroughly which can ensure 100% high quality products sent to you!

3. Quick delivery time: it depends on order Qty and index of process, usually we can ensure you 5days delivery

4. Made-to-order service available:except standard parts like in DAYTON,MISUMI,MOELLER,DME,MDL,DIN,ISO,MSPN etc, also we can make special parts which depends on customers detailed requirements!

5. Excellent customer support: before sales service-in sales-after sales service are available, pls feel free to contact us at anytime!

welcome to contact with us! We will provide you with better service!